We got a call from Kevin M that the instruments he was sterilizing in his Statim 2000 Autoclave were coming out wet and there was water standing inside the cassette

It was completing the cycle without any error code

The first thing we had him do was to run another cycle and listen for the air compressor to kick in during the drying phase

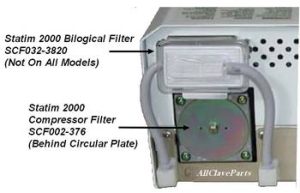

After he completed the cycle, he called us back to tell us the compressor remained silent. So, we told him to remove the round plate on the back of the unit that housed the compressor filter…..to see if the filter was wet or dirty.

The foam filter was soaked with water, which meant it was too late…. The Compressor Was Dead and would have to be replaced

Here is What Happened

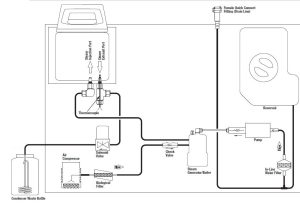

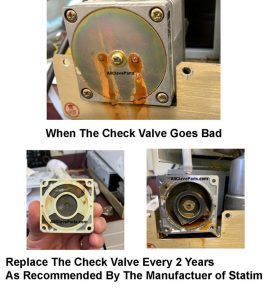

There is a check valve located on the boiler.

Under normal operation, the compressor pumps air into the boiler where it is warmed, and then sends it into the inside of the cassette, to help dry the instruments. The check valve is a one-way valve, which controls the direction of the air, sending it through the cassette.

Click on Image for Larger Picture

Click on Image for Larger Picture

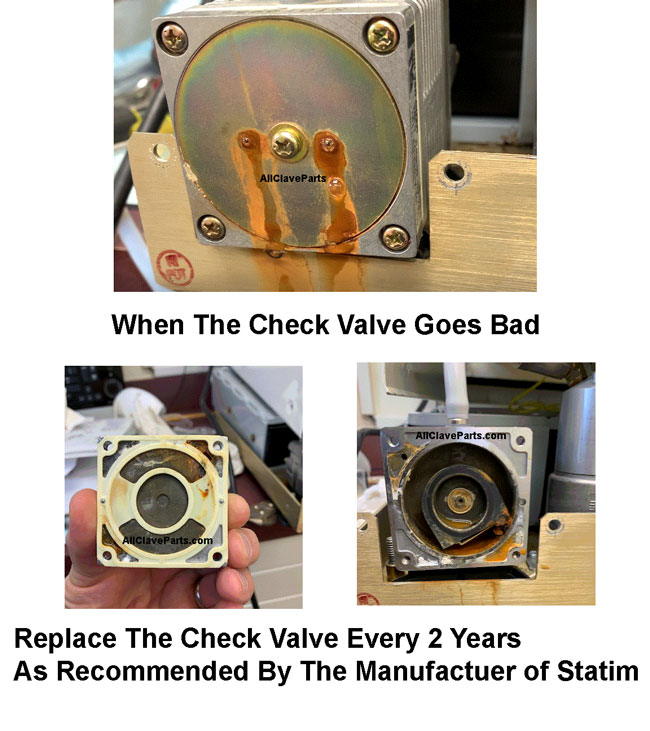

But when the check valve goes bad, it becomes a 2-way valve. Instead of air being pushed into the boiler, the boiler pushes steam backwards into the compressor causing almost immediate damage to the compressor.

How To Prevent It From Happening To Your Autoclave

To prevent this costly repair from happening to your Statim Autoclave there is a simple and inexpensive procedure that takes about 30 minutes or so to complete

Replace The Check Valve

Scican (Statim) Recommends that the Check Valve be replaced every 2 years to be safe as part of your Preventative Maintenance Program. AllClaveParts.com Offers a Guaranteed High Quality Check Valve Kit That Includes Everything You Need to Replace it. You Can Find It Here